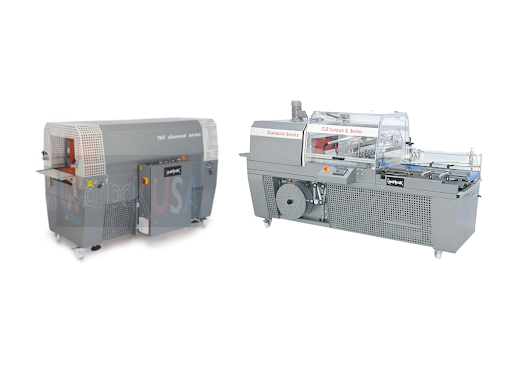

In fast-paced production environments, packaging efficiency and consistency are key. Businesses that rely on shrink wrap packaging need equipment that can handle high volumes without compromising quality. While many companies begin with basic models, upgrading to a shrink wrap machine industrial unit can dramatically improve productivity, packaging precision, and durability.

If you're considering upgrading your current setup, understanding the advanced features of industrial machines—and how they can benefit your operations—is the first step.

Why Upgrade to an Industrial Shrink Wrap Machine?

A standard shrink wrap machine might be sufficient for small batches or occasional use. However, businesses that require speed, volume, and consistent results benefit greatly from the added power and precision of industrial models.

These machines are built for endurance, designed to run for longer periods, and capable of handling more demanding packaging applications. They also offer better sealing, smoother integration with automation systems, and features that reduce labor costs over time.

Core Industrial Features That Add Real Value

1. High-Speed Sealing and Wrapping

One of the most noticeable differences in a shrink wrap machine industrial model is the speed. These machines are engineered to seal and wrap products at significantly higher speeds than entry-level machines. This is ideal for manufacturers and distributors who need to move large quantities of products quickly.

2. Consistent Seal Integrity

Seal quality plays a critical role in product protection and presentation. Industrial-grade sealers use enhanced sealing bars and temperature control mechanisms to deliver consistently strong, tamper-evident seals. This level of reliability is particularly important in sectors such as food, pharmaceuticals, and electronics.

3. Integrated Heat Shrink Tunnel

Many industrial models come with a built-in or integrated heat shrink tunnel. This eliminates the need for separate equipment, streamlining the packaging line. The tunnel ensures uniform shrinking of the film, which results in tighter, more professional-looking packages. This is especially beneficial for items with irregular shapes or fragile surfaces that require even heat distribution.

4. Customizable Heat Chamber Settings

A heat chamber is a vital component of any shrink wrap system. Industrial machines offer better control over chamber temperature, airflow, and dwell time. This allows for precise adjustments depending on the thickness and type of shrink film being used. Products wrapped in polyolefin, PVC, or polyethylene each respond differently to heat, and fine-tuned settings ensure each type shrinks correctly without melting or warping.

5. Conveyor Speed and Versatility

Industrial units often feature adjustable conveyor speeds to accommodate a variety of product sizes and packaging requirements. The versatility to slow down or speed up the process allows better control over workflow and ensures that delicate products don’t get damaged.

6. Durability and Long-Term Performance

Unlike entry-level machines that may wear out with heavy use, industrial models are designed for long-term, continuous operation. Constructed with reinforced steel frames, advanced electronics, and heat-resistant materials, these machines require less frequent maintenance and offer greater reliability.

Choosing the Right Industrial Shrink Wrap Machine

Assess Your Volume Needs

Before investing, it’s important to evaluate your average daily or weekly production volume. Choose a machine that not only meets current demands but also allows for future growth.

Film Compatibility

Industrial shrink wrap machines should support various types of shrink film. Consider what film you use most—such as polyolefin, PVC, or polyethylene—and ensure your chosen model can handle it efficiently.

Integration Capabilities

If your packaging process includes additional equipment such as printers, labelers, or sorters, look for a shrink wrap machine that integrates easily into your current line. Automation compatibility can improve speed and reduce the need for manual intervention.

Support and Maintenance

Choose a manufacturer or supplier that offers reliable customer service, training, and access to spare parts. Having quick support can make a big difference when you’re dealing with tight deadlines.

Conclusion

Upgrading to a shrink wrap machine industrial model is not just about speed—it’s about consistency, quality, and long-term reliability. Features like a built-in heat shrink tunnel, customizable heat chamber settings, and enhanced sealing capabilities give businesses a competitive edge in high-demand environments.

When production scales up, outdated equipment can become a bottleneck. Investing in a high-performance industrial shrink wrap machine helps eliminate inefficiencies, reduce packaging waste, and ensure every product leaves your facility looking polished and protected.

Whether you're expanding your operations or improving your packaging line, the right machine upgrade can deliver a fast return on investment—and keep your packaging process running smoothly for years to come.